Among Napa Valley’s elite brands, there seems to be an odd kind of competition at work. Performance in this contest is not measured by scores or price but is determined by the amount of wine that is discarded along the way to the final product. While these sacrifices of quantity are made in the name of quality, one has to wonder whether this isn’t being taken to an extreme in Napa Valley, where the typical restrictions of budget aren’t necessarily in place. Is this unchecked pursuit of perfection putting human hubris in the way of the naturally sublime? Or do such measures mark the most assured path to greatness? There are many ways to throw away wine in Napa Valley.

“Bulking out,” the selling off of unbottled wine, can happen at any time following fermentation but normally occurs just after blending. At the highest level, a final blend is a pure vision, uncompromised by such considerations as the volume of wine on hand. This can result in a substantial amount of “extra” wine, which the winery can either assemble into a second label or else release under an anonymity clause on to the bulk market. More than one savvy brand has been built around the blending and repackaging of discarded wines from Napa’s top estates, offered to the consumer at a fraction of the cost of their manufacture. But what the vintner loses in income they gain in bragging rights: It is not uncommon to hear of estates bulking out 10, 20, 30 percent or more of their total production each year.

Crop-thinning is another method of forfeiture in the pursuit of excellence. So-called “grand cru” yields of between 1.5 and 2.5 tons per acre seem to be the ideal. Low crop loads result in more concentrated fruit, and promote even ripening. Critics complain that such low tonnage encourages overripe grapes and that a more reasonable crop load would extend the maturation process and preserve the natural acidity of the grapes. Nonetheless, severe crop-thinning remains a standard practice for most of the high-end brands, especially among those that control their farming.

And finally, slotted in between crop-thinning and the bulk market, is the fruit sorting that accompanies harvest. It is during this act that the most variance, and excess, in methodology can be witnessed-due in large part to technological innovations over the past few years.

Extreme positions on sorting run from the deliberate inclusion of stems and leaves, to the mechanical removal of all but the most perfect berries. In conversing with a range of winemakers recently, it became abundantly clear that many regard this step as among the most critical of all the stages of winemaking. To some, sorting bore an even greater significance as a touchstone for their wine values; the decision of what exactly they did or did not allow in their fermentation tanks was representative not only of their approach to terroir but also of their theory of excellence in wine.

Sorting uniformity

Ric Forman, who has been making wine in Napa Valley since the late 1960s, thinks that things have gone too far. “Back in the 1970s, we harvested the grapes into 5-10-ton gondolas, and mashed the fruit all up with augers when the time came to transfer them into tank. And you know what? The wines were fabulous.” Though he has since modernized his practices, today he sorts mostly in the vineyard, utilizing only a short vibrating table inside the winery. “These days we [the winemakers of Napa Valley] carry the clusters into the winery on silk pillows and lower each berry down into the tank by hand, and I can’t honestly say that the wines are the better for it.” Forman is far from being the only one who thinks this way: Critics of today’s intense sorting methods insist that perfect uniformity of berry makes for perfect uniformity of wine- in other words, that the process strips the wine of its potential complexity.

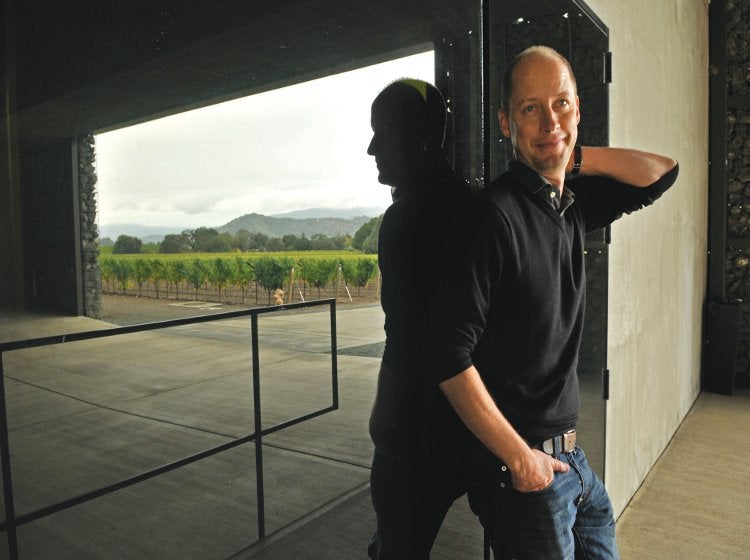

Tod Mostero, the talented winemaker at Dominus, is a passionate proponent of sorting. He claims that the issue at stake isn’t complexity; it’s purity. “Leaves and stems don’t communicate terroir; neither do new oak barrels. You have to get all that ‘noise’ out of the way in order to truly hear the land.” Dominus is one of a growing number of wineries in Napa that use an optical sorting machine. These hulking pieces of equipment are spinoffs of technology that has long been used in the produce industry. They were customized for wine application by two French companies-Bucher Vaslin and Pellenc-and released to the market in 2008. Dominus trialed a model in 2009 and loved it, purchasing its own machine in time for the 2010 harvest. As the name implies, the fruit selection process is done optically: A computer takes a series of photographs of the material that passes its sensors, immediately ejecting, via directed blasts of air, any MOG (material other than grapes). The grapes themselves are also subject to judgment. The winemaker is able to set the parameters delineating ideal color, shape, and size of berry. This prevents any underripe, raisined, or even rotten berries from passing through into the tank.

Another advocate of optical sorting is Michael Silacci, winemaker at Opus One for the past 12 years. Possessing a rigorous, scientific mind, Silacci staged measured experiments before committing the winery’s resources to the technology. He found that instead of culling more fruit than a table manned with people, the optical sorter actually culled less. The reason? Fewer babies, more bathwater. When sorting occurs in the vineyard, or even by hand, a considerable amount of good fruit gets thrown out with the bad. Now that Opus One has gone optical, Silacci estimates that they actually produce 2 percent more wine per year. That extra income, in addition to the labor savings, ensured that such an expensive piece of machinery (upward of $200,000 apiece) paid for itself within a single year.

Randy Dunn, maker of some of Napa’s most soughtafter wines, stands firmly in the opposition camp. He doesn’t even own a vibrating table. “We do not sort our grapes at the crusher-that is for the new wave of geek winemakers that want to make that slippery stuff, to drink tonight. We sort in the vineyards.” He adds, “I’ve made some of my best wines by throwing the stems back in.” For Dunn, the phenomenon of extreme sorting is nothing more than fashion, a stylistic decision made by winemakers who are afraid of tannin. “They want to make the style of wine that is popular. But if you take out all those stems, you take out the guts.” When asked about optical sorting, Dunn was incredulous: “I wonder what it is they think they have that they are so desperate to get rid of?” For both Silacci and Mostero, the resounding answer is raisins. In Napa Valley, the sun can be just as much an enemy as a friend, and the long, dry summers and end-of-season heat spikes can desiccate even the healthiest clusters. For conscientious winemakers such as Silacci and Mostero, both of whom strive to create balanced wines with notable freshness and moderate alcohol, raisins are the enemy. And they have found that optical sorting is the most efficient way to remove the offending grapes.

Airbrushing the vintage

Abe Schoener, the philosophy professor turned controversial winemaker behind Scholium Project, takes issue with that position. He finds that vintage characteristic is a critical and often marginalized element of terroir. “Come harvest time, the presence of either rot or raisin is an expression of what happened in the vineyard that year. If you reject either, you aren’t telling the whole story of your vineyard.”

At Scholium, Schoener executes very spare sorting, and what little fruit is rejected is culled from the vine prior to harvest. “We direct our farming so that nothing comes off the vine that I don’t want to make wine from.” But in a year like 2011-a cold, wet vintage marked by a preponderance of rot on even the hardiest of grape types-an anti-sorting stance can make for a difficult position. Sticking to his philosophical guns, Schoener allowed molded clusters into his fermentation tanks. Rather than obsessively sort, he simply shifted his winemaking in service of the vintage. But this type of bold decision-making can only happen at a winery like Scholium Project, whose fan base values the brand’s artistry over consistency.

The conscious decision never to sort is certainly one path to individualism, but Denis Malbec, former winemaker for Château Latour and current Napa Valley consultant, finds that sorting can be its own route to distinction. Echoing Mostero’s view, Malbec muses, “Sorting will isolate the purity of your terroir and will tie your wine firmly to one piece of earth and no other.” He claims that exactly this sort of diligent winemaking is the antidote to the “international style,” which he characterizes as too much oak, too much ripeness, and too little transparency.

Malbec allows that great wines have been made without sorting, but he feels that in today’s competitive world of wine, you need to go the extra mile to distinguish yourself, especially at the high-end: “Every little detail counts when you are operating at a very high level.” Denis Malbec and his wife May-Britt are currently the consulting winemakers behind both Kapcsándy and Blankiet, two of Napa’s most highly respected estates.

They are admirably active in the vineyards and perform their first selection at the vine. The clusters that pass muster and make it into the winery are then examined once more before destemming. Following destemming, a small vibrating table removes any raisins and shot berries; then the real action starts. At Kapcsándy, the Malbecs now employ 18 different people to man the lengthy sorting table, removing any berries that appear less than perfect.

At Blankiet, they hire even more. This type of sorting is a slow, painstaking, and expensive process, but at Blankiet and Kapcsándy-both of which process only a handful of tons each day-there is both the money and the time. “If I worked for a larger winery, I would absolutely buy an optical sorting machine,” admits Malbec. At Opus One, where they produce between 20,000 and 25,000 cases of wine per year, the increased efficiency of the optical sorting machine makes a big difference. “Fruit quality dictates wine quality, and we like to get the fruit from the vine to the tank in the shortest possible amount of time,” says Silacci. Prior to the optical sorter, they could process only 4 tons per hour; now they average 7.5 tons per hour- nearly twice as fast. This also means they can get the fruit off the vine more rapidly, that nothing is left out to hang because of the processing limitations of the winery. The scheduling of incoming fruit is a rarely discussed balancing act that all but the smallest of wineries must perform every harvest.

The social question

Denis Malbec goes on to address another point of sensitivity surrounding increased mechanization in wineries: fear of human replacement. “I am a social winemaker,” says Malbec. “I like to work with people, hire people, participate in the local economy.” He also believes that, for a small operation, there is nothing better qualified than eyes and hands. For their part, Dominus and Opus One seem to agree-both wineries supplement their optical sorting with extensive human labor. At Dominus, they even have manned sorting tables positioned both before and after the sorting machine.

This might prompt some to inquire why an optical sorting machine is even required? If it isn’t sufficient to reduce human error and labor, then what exactly is its purpose? The answer is that these extreme sorting measures, whether mechanized or human, aren’t about increasing efficiency or saving money; they’re about proving beyond reasonable doubt that you did everything in your power to produce the greatest possible wine. While extremely useful in a rot-filled year like 2011, even the staunchest pro-sorter admits that, in more textbook years like 2012 and 2013, these measures function more as a security blanket than as anything particularly essential. But when you’re charging several hundreds of dollars for your wine, isn’t there an unspoken obligation to the consumer to pursue excellence whatever the cost?

The questions that naturally follow are polarizing. Are all of these extreme measures actually qualitatively worthwhile, or has the premium end of the wine industry gotten lost in a game of one-upmanship? Both sides have their camps. Ric Forman believes in economy of gesture, a point of maximum return. Anything beyond that is what he calls “emotional winemaking,” or making wine by sound bite. In his corner are the many great wines of California’s past-wines made without much sorting, from grapes that were roughly handled in the field, from vines that probably contained a fair amount of virus-all things Californians seem very afraid of today. And in the other camp is an army of modern winemakers, many with bottomless pockets, determined to spare no expense in the pursuit of perfection. A quest that, as Denis Malbec explains, is “a delicate dance and a balance. There is no easy direction; it is just something you have to keep working toward.”